What is the best blade material?

There are several varieties of varieties of objects that are used to make knives. Above most producers have their own special characters and instruments that they use in their knives. Each has benefits, problems and difficulties. For our purpose we will keep it simple and focus on the following things.

Plain Carbon Steels

This is done by combining a small amount of manganese and carbon and iron. These carbon steel metals are usually shown in the 10XX format. 1095, 1055, 1045 are examples of this. XX number in this problem tells you how much calcium is used for mixtures. So 1095 can have a carbon 95%.

The benefits of carbon blades are the easiest to be sharp. Another advantage is carbon over the knife is easy to throw a split with a flint in the pit. Wrong things are easy to start getting rid of. If you want carbon blade towel you will need to keep the oiled blade to help prevent coal. You can also force petina knife to minimize the process of rust.

Alloy Steels

Stainless Steels

This is the largest hunting group. When the mixture begins to contain more than 12% chromium it is considered as empty iron. The carbon is about 30% to 1.20% in these areas.

This is the largest hunting group. When the mixture begins to contain more than 12% chromium it is considered as empty iron. The carbon is about 30% to 1.20% in these areas.

One of the greatest spare parts of the stainless steel is the anti-corrosion resistance. That does not mean that an empty metal knife will not get rid of it but it takes a lot of attention. And the stainless steel knife will have a better finish than carbon dioxide.

The stainless steel remains that it is more difficult to be clever than the cultural pillars. Another danger to my opinion is that there are many empty empty trucks there that there is a great difference in the quality of this feature. The S30V is regarded as one of the non-teaspoon-free teaspoons for making knives.

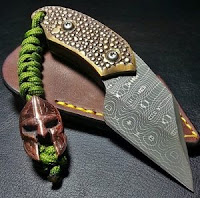

Damascus Steel

Damascus is made by filtering two kinds of steel together again and again. The steel then etched acid produces a different unique color and diagram. Because of this time, the process of requiring Handmade Damascus Steel Brass Bolster is expensive and is often used solely on traditional arms.

Comments

Post a Comment